Distillation is one of the most widespread basic operations of chemical engineering. It is essentially a thermal technique that separates the different components of a liquid current taking advantage of its different volatility or boiling temperature.

The associated technology has evolved a lot in recent decades and features a multitude of configurations and modes of operation.

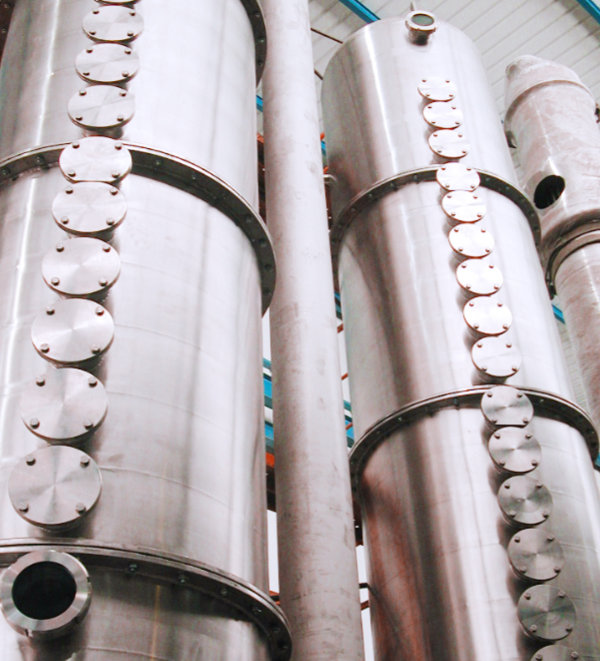

At Grupo Vento we have extensive experience in the design, manufacture and commissioning of this technology. Simulation, laboratory and pilot plant testing tools are critical to predicting the correct performance of the designed units.

Applications:

In the alcohol industry, for the purification of alcohols.

In the must and juice industry, in operations as important as most desulphitation or deoling of citric juices.

In the biodiesel sector, for the purification of different components (biodiesel, methanol, glycerin..).

In the environmental sector, as a main or complementary technology (in the processes of minimization of industrial liquid discharges by evaporation), often allowing not only purification, but the obtention of recoverable volatile components; with the economic return that this entails.